Revision of HV , high voltage and transformer substations

High Voltage and Explosive Environment Revision

We have staff trained for high voltage and explosive environment ATEX inspections).

Professional inspection and professional test of HV connections, substations and HV lines is no problem for us. Our staff has many years of experience with these types of equipment.

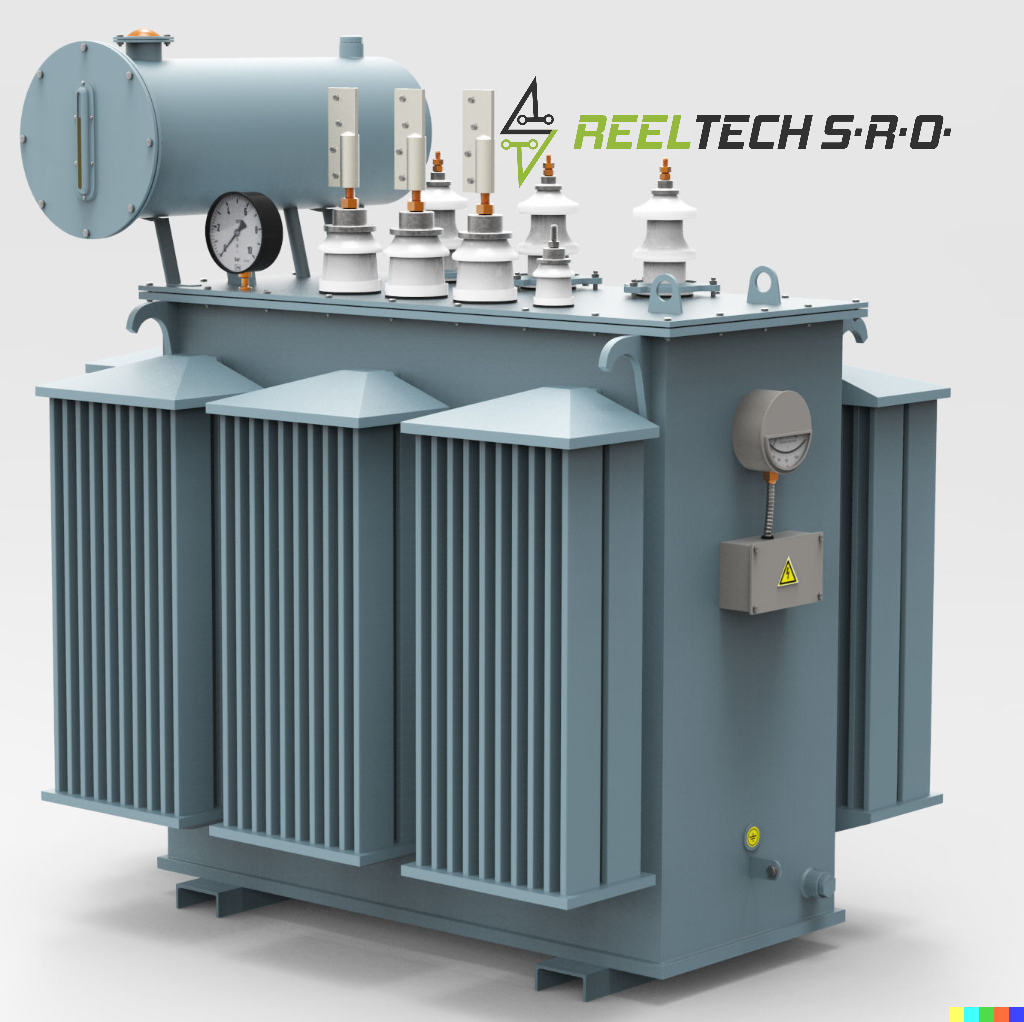

Our routine activities include Professional Inspection and Professional Test - revision of high voltage connection, revision of 22kV transformer station and revision of high voltage lines.

We also carry out complex maintenance of the substation, transformer measurement and measurement of high voltage connections. Even pole and kiosk transformer substations do not pose a problem for us.

Substation maintenance is very important for your business as it supplies power to all areas of the business. It changes the standard voltage of 22kV to 400V, it includes a HV substation, transformer and network protection.

The inspection and maintenance of high voltage (HV) equipment is essential to ensure the safety, reliability and efficient operation of the electricity network. Here are some reasons why it is important to carry out regular inspection and maintenance of HV equipment:

- Safety: safety is a priority when working with HV equipment. Inspection and maintenance enable the detection and elimination of potential safety hazards such as fault conditions, insufficient insulation, improper grounding, and other hazards. This minimises the risk of electrocutions, explosions or fires.

- Reliability: inspection and maintenance guarantee reliable operation of HV equipment. Regular inspection and testing of the equipment allows possible faults to be detected and repaired, minimising the risk of power outages. This is particularly important for the operation of key equipment and infrastructure such as hospitals, industrial plants or public networks.

- Extending the life of equipment: regular maintenance of HV equipment contributes to its longer life. Maintenance minimises wear, corrosion and environmental impact on the equipment. Proper adjustment, cleaning and replacement of worn parts ensure optimum equipment functionality and prevent early equipment failure.

- Efficiency: the revision and maintenance of HV equipment also contribute to increased energy efficiency. Checking and optimising equipment parameters such as voltage, current and energy loss allow energy and financial savings. Regular maintenance also minimises the need for costly repairs and replacement parts.

- Compliance with regulations and standards: Inspection and maintenance of HV equipment are necessary to meet electrical safety regulations and standards. Distribution companies and SR Rules have precise guidelines and rules that require regular inspection and maintenance of HV equipment. Compliance with these is important for legal and safety compliance.

In summary, the inspection and maintenance of HV equipment are key to the safe and reliable operation of the power grid. They ensure worker safety, minimize outages, extend equipment life, increase efficiency, and comply with regulations and standards.

We provide the following services:

- HV transformer measurement

- Inspection and maintenance of HV equipment / switchgear, busbars

- Inspection and maintenance of LV equipment

- Revision of earthing and lightning conductor

- High Voltage Protection Test

- Transformer insulating oil insulation property test

- Inspection of the equipment and integrity of the substation

- Transformer station maintenance, dungeons , kiosk , kiosk transformer station

- Thermal Imaging

- Inspection and revision of high voltage HV connection

All electrical equipment and systems that operate at voltages above 1 kV are subject to high voltage inspection. The most common equipment subject to high voltage inspection includes

Transformers are devices that change the electrical voltage from one level to another, most commonly 22kV to 0.4kV

High voltage lines: High-voltage lines for the transmission of electricity at high voltage.

High voltage switches: High-voltage switches , which are used to switch electricity on and off.

Protective devices: Protective devices are designed to protect electrical equipment and systems from all forms of damage.

Among other facilities, which are often checked at high voltage, also include components such as capacitors, fuses and electrical sockets.