Service of Photovoltaic Power Plants

We service and maintain photovoltaic power plants.

Technical status audit, automatic data reporting

- During the practice of servicing photovoltaic power plants, we often encounter almost layman's questions - what do we actually do? Are PV systems frequently malfunctioning?

- How can we localize individual faults? Work on photovoltaic installations, whether on small rooftop installations or large flat-plate power plants, consists not only of routine electrical work, but often also of preventive inspections and specific tasks on entire installations using special measuring instruments that can identify damaged panels or panel sections that are not recognizable to the naked eye or a conventional measuring instrument. Preventive measurements of wiring and measurement of transient resistances are also common. We strive to make the PV plant work properly as a whole, with as little power loss as possible.

What all needs to be done with a photovoltaic power plant?

Operating

- Online monitoring of PV application operation and monthly evaluation of production and performance.

- Making the monitoring software available to and training the end user

- Energy administration

- Complete takeover of all activities such as periodic preparation of documents, submission of applications and reports for all entities such as ÚRSO, OKTE, Distribution companies and electricity traders

- Registration of the photovoltaic application and the end user in OKTE and regular sending of reports to the system

- Representation of the end user before state institutions such as the building authority, customs, etc.

Service and maintenance

- 24/7 hotline emergency service with troubleshooting onset within 24 hours

- warranty service: free of charge for up to 24 months within the warranty period for the entire work, including replacement of defective equipment

- after-sales service: service operations are covered by a flat fee and spare parts according to the status of the extended warranty period of the product. Equipment within the warranty period will be replaced free of charge

- Preventive maintenance and prophylactics of equipment within the warranty period

- 12-monthly perodic check of the stability of the support structures and the fixing of the photovoltaic modules

- 12 monthly periodic diagnostics of the PV inverter condition, tightening of connections and terminals and replacement of air filters.

- Online periodic monitoring and diagnostics of PV inverter status and error messages.

Reporting data to OKTE

- Every PV plant above 10kW must comply with state regulations and standards and one of them is reporting data to OKTE.

- We provide a fully automatic and functional solution

- Automated reporting of metered data to authorised recipients (OKTE, SEPS, RDS) is a process that simplifies and streamlines the exchange of data between these entities. This process consists in the automatic sending of data from metering devices and meters to a central server and the subsequent presentation of this data in real time to the authorised recipients.

- In practice, this means that metering devices, which can be smart electricity meters for example , send the measured data to a central server where it is processed and stored. This data is then automatically reported and distributed to authorised recipients such as OKTE (Trade Union Communication and Transaction Platform for Electricity), SEPS (Slovak Electricity Transmission System) and RDS (Regulatory Authority for Network Industries).

- This automated process of reporting measured data enables a fast and efficient exchange of information between these entities, contributing to better coordination and planning of energy activities. In addition, it helps to minimise costs and improve overall efficiency and performance in the energy sector.

Photovoltaic power plant audit and condition assessment.

- A PV health audit is a process that focuses on assessing and evaluating the condition of solar panels and related equipment. This process can be carried out either as a precautionary measure to minimize the risk of problems and failures, or as a tool to identify and address specific problems that have already arisen.

- During the audit, a physical inspection of the solar panels and equipment is first carried out to assess their appearance, integrity and functionality. It is also determined that all components are functioning properly and that there are no overloads or other power supply problems.

- In addition, the audit also focuses on assessing the efficiency and effectiveness of the solar system, including an assessment of the performance of the solar panels and the overall performance of the system. This can help to identify areas where efficiency improvements are needed, thereby improving the performance and efficiency of the PV system.

- Based on the results of the audit, a plan can then be drawn up to improve the technical condition of the PV system and optimise its performance. This ensures the safety and reliability of the entire system while minimising the risk of faults and outages, ultimately contributing to cost savings and increased solar system performance.

- This audit can be a very useful tool todetection of installation company errorswhich installed the solar system.

- One way a PV audit can uncover mistakes made by the installer is by assessing and evaluating the physical condition and functionality of the solar panels and related equipment. If the solar panels are not performing as expected, it may indicate that the installing company did not install the panel properly or that there is not enough sunlight in some areas. Another factor that may indicate an error by the installer may be improper placement of the solar panels, which may result in inadequate performance or inefficiency.

- In addition, the audit also focuses on assessing the efficiency and effectiveness of the solar system. If it is found that the solar system is not performing as expected, it may be a sign that the installer did not use quality solar panels or did not select the right components and parts.

- Based on the results of the audit, it is then possible to identify specific problems in the solar system and propose solutions to fix them. This ensures the safety and reliability of the entire system while minimising the risk of faults and outages. This ultimately contributes to cost savings and increased performance of the solar system, while also revealing mistakes made by the installer and providing recommendations for their correction.

95% all faults detected by monitoring

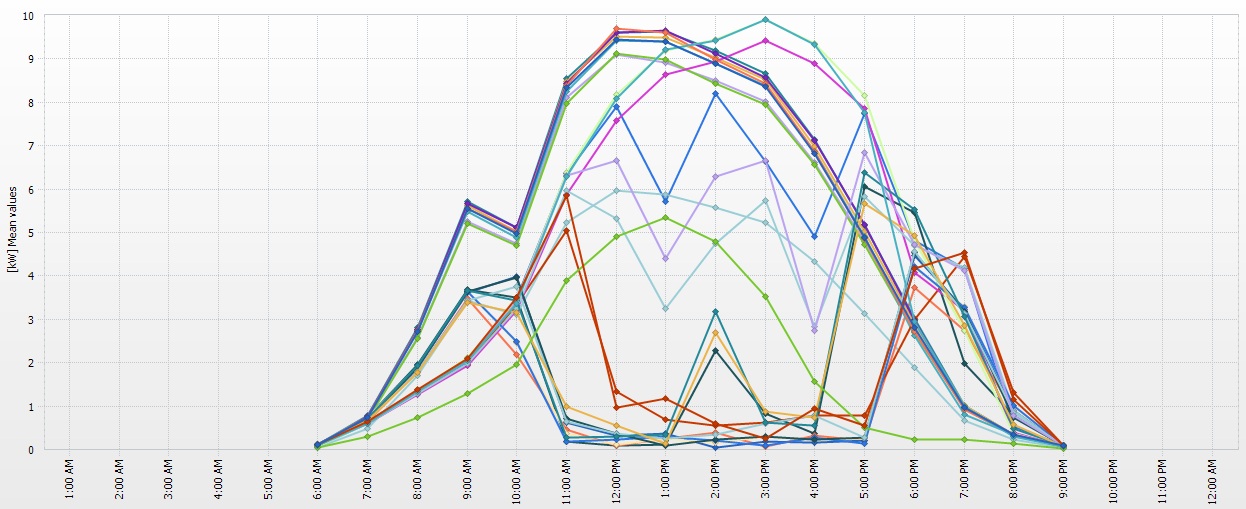

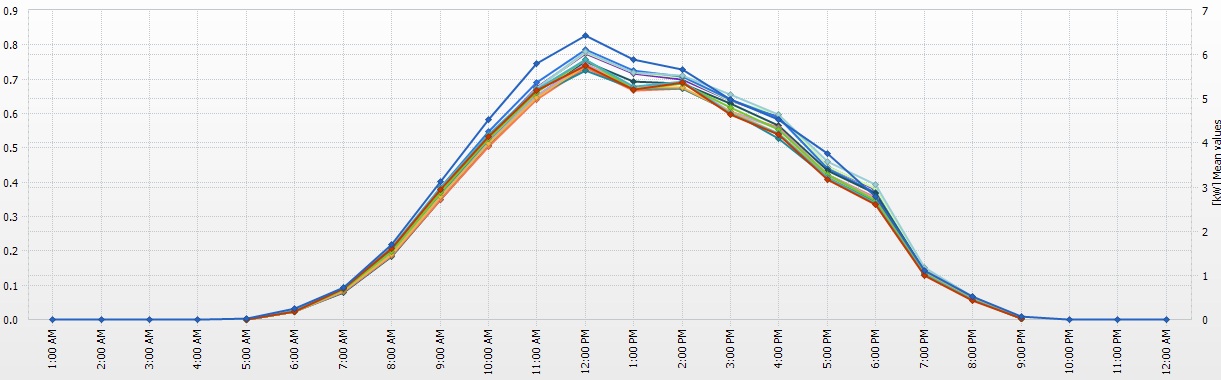

Many times we meet people who consider monitoring unnecessary. However, the opposite is true. The right type of monitoring can identify a fault on a device almost instantly, allowing a quick assessment of the fault and a subsequent response in the form of repairing the fault. Variations in the performance of individual inverters often cannot be evaluated immediately, but within a few days the technician is informed about the functionality of individual inverters or sections of the PV plant. The attached pictures show the difference in performance of the individual inverters. The installation of the monitoring revealed large variations in the power generation in the different sections of the PV plant, causing an average 50% loss in power output. After the monitoring was observed and the fault was detected, the correction was made by properly adjusting and correcting all the deficiencies and the power waveform became linear again without any outages and power loss, which is shown in Figure 2.

Correct setting of inverters is important

Most of the inverters were installed with default settings for the region or according to the requirements of the power companies. In many cases, it happens that these settings cause serious shortcomings in production, for a quite simple reason - the installation in individual locations and the intensity of solar radiation may not always be ideal. Poor stringing of the panels on the DC side also does not contribute to inverter operation. Therefore, it is often necessary to adjust the inverters appropriately to the local grid characteristics, thus limiting power losses, system failure rates and increasing the overall lifetime of the equipment. For comparison, the change in performance before and after service intervention and comprehensive inspection