Measurement of insulating properties of electrophoretic painting bath

Performance of specialised measurement, inspection and revision of car body paintwork. It is used to determine the condition of surface properties. It is carried out using two measurement methods, it is mainly carried out in the automotive industry. Measurements and revisions of paint and paint application areas are carried out, while all safety conditions with regard to the environment and explosive atmosphere must be observed. During the inspection and testing, the paint bath must be drained, dried and all elements of the anodic-cathodic technology switched off.

Measurements aimed at detecting faults in the envelope, leakage currents and properties of physical variables, while checking the paint bath, its properties and the overall safety of the area. The inspection is carried out during the shutdown period and all emulsion and paint must be drained.

How does painting work ?

Therefore, it is important to understand the current status of the painting process and failure mechanism and the possible influence of the galvanized substrate and the permanent presence of aluminum.

The continuous process includes:

- before finishing- states full phosphating by immersion,

- electrophoretic deposition of the base colour - cathodic application of a 25 to 30 µm film,

- Alignment application - auxiliary spray layer on 30 - 40 µm,

- Anti-flying pebble primer - applied to wet specific parts 20 µm,

- application of the base colour - final top coat 15 - 25 µm.

Each surface treatment increases the gloss and colour depth by 35 - 50 µm.

- Powder coating belongs to the group of so-called industrial coatings. It allows to modify the surface of many materials. It consists of mixtures of resin, pigments and other components. They have a dry and powder consistency. When used, powder paints do not dilute or dissolve in any liquid. They are always ready for immediate use. It has an excellent finish with the best resistance to corrosion and UV deterioration. Individual finishing based on a choice of a wide range of materials, textures and colours. Epoxy, epoxy-polyester, polyurethane, acrylic or polyester can be selected. Acrylic painting is used in the automotive industry. The textures can be smooth, grooved, grained or metallic. Paints can be heat resistant, for use in high temperature environments. It has gained its popularity from its practical use. Powder coating has ecological and economic advantages with a quality result.

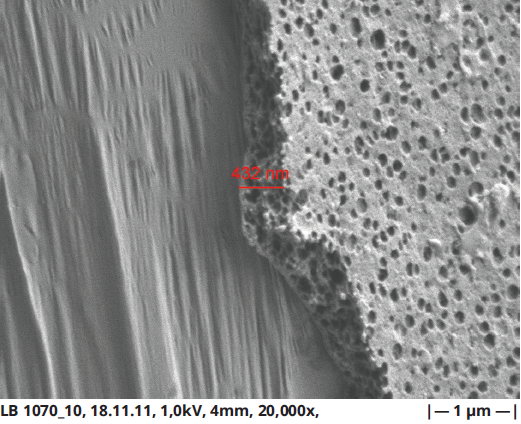

Fig. 16 Raw edge of non-metallic porous parts, temporarily protected on a metal substrate

Powder varnishes with the addition of GMA (glycidyl methacrylate) acrylic resin and dicarboxylic acid.

Powder coatings are free-flowing micronized particles that are used in fluid bed reactors or electrostatically sprayed onto a metallic or conductive surface. The resulting powders are then melted into particles, cured to produce a very hard and high gloss surface. Powder coating has major advantages over coating techniques in that thin layers (30 - 40 µm) can be formed at relatively low temperatures (150°C) without solvent. It has zero VOC. Although a number of different chemical resins are used for powder coating glycidylmentaryl methyl acrylate (GMA), powder coatings are known for their high gloss, durability and abrasion resistance. GMA resins have a very high functional epoxy (up to 60 equivalents) and the addition of GMA resins. The resulting coating thus has excellent solvent resistance, unlike conventional organic solvents, good weather resistance, and has high gloss and excellent adhesion to metals. Consequently, these materials are suitable for and automotive production. The disadvantage of GMA resins is that they can be brittle due to the cross-linked density in GMA and C12 - Dic acid is currently the most commonly used in GMA, and C18 - Dic acid has the potential to improve the flexibility and durability of the resulting coating. Due to the elastic C18 methylene chain. C18 acid has a melting point of 124°C and C12 has a melting point of 128°C . Therefore, they can be put into existing production lines without modification.

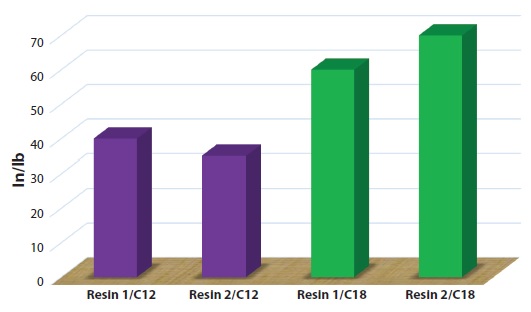

Fig. 17Graph of the effect of powder paints with the addition of C12 and C18 acids in impact resistance.

C18 acid exhibits high gloss, durability, resistance to dissolution and good adhesion. When C18 dic acid is used as an additive in GMA powder, the resulting coating has twice the impact resistance, compared to the use of C12 acid.

Fig. 18Modern booth for automated industrial powder coating (left) and the inside of the booth during application (right).

- Electrophoretic ( electrophoretic ) painting has been expanding significantly in recent years in the field of organic surface treatments. Anaphoric and especially cataphoretic painting of metal parts is nowadays the basis for almost all body parts in the automotive industry. Depending on the required throughput capacity, the properties of the parts to be treated, the spatial possibilities and the chosen technology, specific plants are designed by their assembly into a technological unit [56]. Shape-complex products are painted with perfect results and with better corrosion-resistant properties. Electrophoretic painting is carried out in a bath. The products are immersed in diluted paint with water containing low solids content. The particles are bonded to the surface of the product by the electrical DC voltage generated between the electrode and the product. The layer thus formed has excellent adhesion even to complex shapes, i.e. even the edges of the product.

Drying of varnishes

It requires a significant cost of energy, time and other variables. Conventional emitters consume more energy than is needed for drying and curing the paint layer. 60 % of incandescent energy is visible light from 0.3 - 0.7 µm and near-infrared 0.7 - 2.5 µm. These types of energy are not needed by the painting process. A significant contribution to solving the problems is the use of infrared technology based on functional ceramics.

Enriching the varnish with functional ceramic additives in a ratio of 0.5 - 2 % of the varnish volume. The drying and curing of the varnish is more economical in terms of time and energy. Their costs are reduced by 30 % compared to processes in which varnish is used without the addition of functional ceramics. The lacquered surface acquires new and interesting functional properties.

Drying and curing of some types of automotive paints with the addition of functional ceramics takes a maximum of 5 minutes, at low temperatures in general. The automotive lacquer spreads in the normal way when the surface is heated to a temperature of less than 130°C and for 30 minutes. The adhesion and durability of the enriched painted surface to mechanical stress is increased by the technology. The strength is increased by a factor of 1.5. The adhesion is also increased, even with repeated violent movement of the metal it is not possible to remove the coating or create cracks. There is no need to carry out difficult operations - degreasing of painted parts.

The use of functional ceramics in the automotive industry greatly improves the quality of the coating and reduces the number of technological operations, and the energy consumption is reduced.